How to customize the hydraulic press?

Hydraulic press is called universal hydraulic press because of its wide range of uses. Customers have different requirements for machines in different application fields. Therefore, we will customize according to the different needs of customers. Machine table size, opening height, slider stroke, speed, pressure and so on can be designed according to customer requirements. If you cannot provide the exact parameters of the machine, just tell me the product you want to produce, the size of the product and the information of raw materials. Our professional technical team will give a reasonable machine design scheme according to your products.

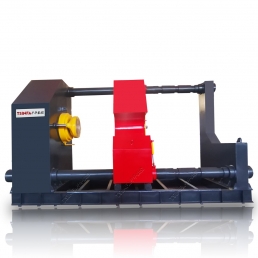

Why purchase a custom hydraulic press?

Ordinary standard machine has simple function and fixed parameters. It is possible to increase the customer’s unnecessary purchase cost due to the excessive size of the opening, slider stroke and worktable, or it may be too small to use. When the working speed, the traditional structure layout and the single pressing function of the standard machine cannot meet the production needs of customers, the customers should choose to customize the hydraulic press. For example, if customers want to produce SMC/BMC products, according to the characteristics of composite products need to be heated molding. SMC/BMC hydraulic press will add slow back function and temperature control system on the basis of standard press. Slow back function can reduce the tear of the product when opening the mold, so as to improve the qualified rate of the product. Customers can also choose PLC, servo motor, pressure sensor, displacement sensor and so on according to their needs. Compared with the traditional standard machine, the customized hydraulic press can better meet the needs of customers and save the purchase cost of customers. Is the best choice for customers.

Custom hydraulic press installation and use.

All our machines go through strict debugging before leaving the factory to ensure normal operation. The machine will be shipped with detailed instructions in English. If the overall dimensions of the machine can adapt to container transportation, we will ship the whole machine without disassembly. The customer only needs to connect the corresponding oil pipes and wires according to our marks, fill the tank with No.46 anti-wear hydraulic oil, and connect the external power supply then the machine can be use. If the size of the custom hydraulic press is too large to be loaded into the container, we will disassemble the machine and transport it, but we will provide detailed videos, pictures and text instructions to help customers install the machine. Our after-sales team can provide online machine installation and use guidance.