Tsinfa is a professional supplier & manufacturer of manual lathe machine in China.

The price of manual lathe mainly depends on the rotary diameter and length between centers, as well as the weight of the workpiece. Different specifications, different prices. The specific price can be contact sales department: Give us a call at +86-15318444939, and talk to one of our expert reps. You can also fill out our: contact form.

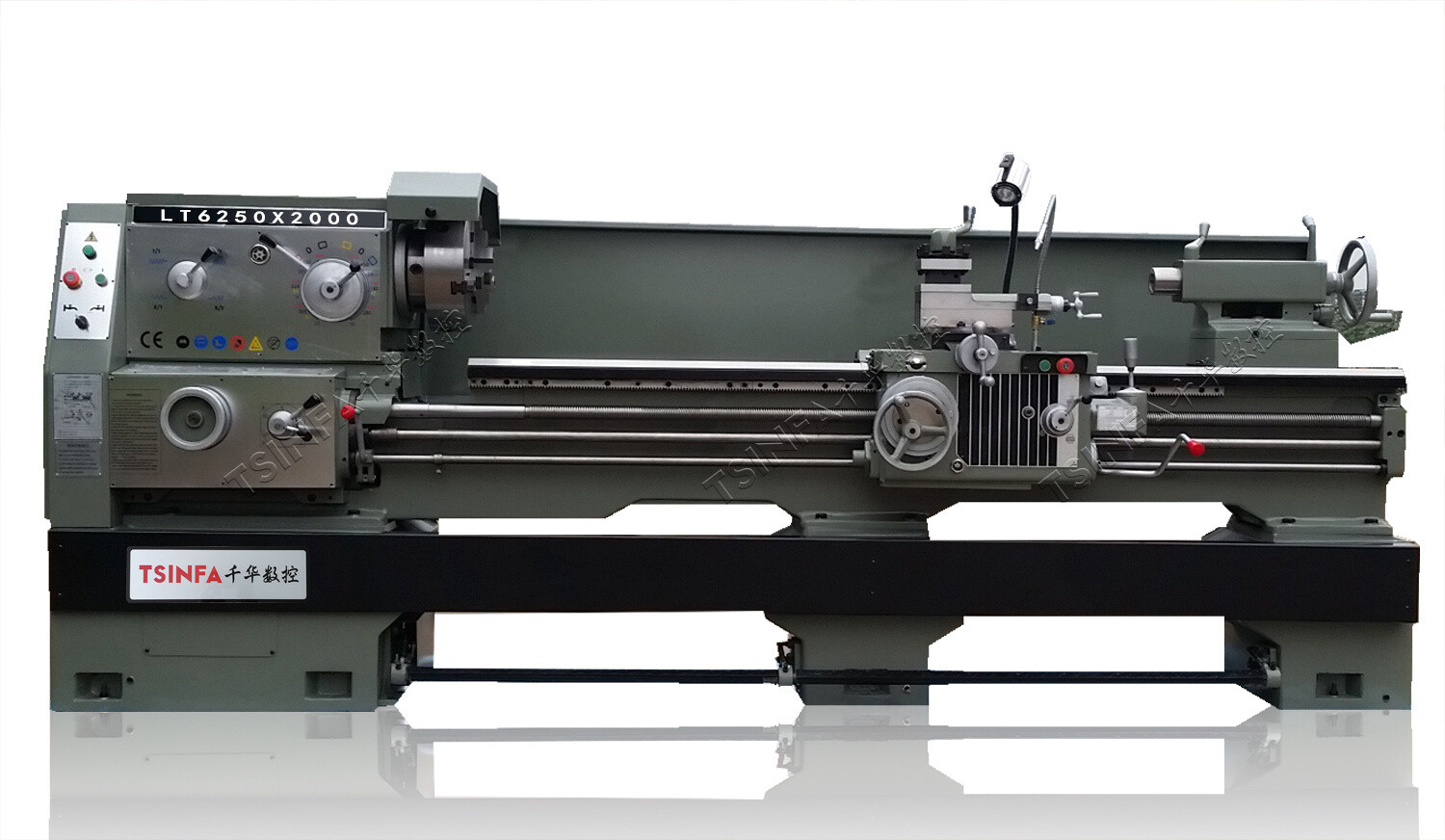

Manual lathe machine images and specification (Hot sale):

Heavy duty manual lathe machine LT6240

Swing over bed: 400mm

Spindle bore: 52/80/105mm

Distance between centers:

750/1000/1500/2000/3000/4000mm

Heavy duty manual lathe machine LT6250

Swing over bed: 500mm

Spindle bore: 52/80/105mm

Distance between centers:

750/1000/1500/2000/3000/4000mm

Heavy duty manual lathe machine LT6266

Swing over bed: 660mm

Spindle bore: 52/80/105mm

Distance between centers:

750/1000/1500/2000/3000/4000mm

Heavy duty manual lathe machine LT6280

Swing over bed: 800mm

Spindle bore: 52/80/105mm

Distance between centers:

750/1000/1500/2000/3000/4000mm

Light duty manual lathe machine LH6240C

Swing over bed: 400mm

Spindle bore: 80mm

Distance between centers:

1000/1500/2000mm

Light duty manual lathe machine LH6250C

Swing over bed:500mm

Spindle bore: 80mm

Distance between centers:

1000/1500/2000mm

Light duty conventional manual lathe machine LH6260C

Swing over bed: 600mm

Spindle bore: 80mm

Distance between centers:

1000/1500/2000mm

Medium duty manual gap type lathe machine LT6236, LT6240

Swing over bed: 360mm 400mm

Spindle bore: 52mm

Distance between centers:

750/1000/1500/2000mm

Medium duty manual lathe machine LH6251

Swing over bed: 510mm

Spindle bore: 52mm

Distance between centers:

1000/1500/2000mm

Medium duty manual lathe machine LH6260

Swing over bed: 600mm

Spindle bore: 52mm

Distance between centers:

1000/1500/2000mm

Small Manual lathe machine LH1440K

Swing over bed: 360mm

Spindle bore: 40mm

Distance between centers:

1000/1500mm

Manual heavy duty lathe machine

Swing over bed: 630-1600mm

Spindle bore: 104-520mm

Distance between centers:

1500-6000mm

Types and solutions of lathe faults

Lathe machine is a kind of metal processing machine we often see. In the process of production and processing, the lathe machine will inevitably encounter some faults.

It can be divided into main engine fault and electrical fault according to the different parts of the fault;

According to different properties, it can be divided into abnormal operation of lathe itself and defects of machined parts;

According to the different parts of the system where the fault occurs, it can generally be divided into electrical system fault, mechanical system fault and hydraulic system fault (the air pressure and hydraulic pressure are roughly the same);

The following is a brief description of several common lathe faults and their troubleshooting methods.

- Bearing fault

Transmission shaft is the core component of lathe to realize machining. It carries the main load when working, so it is one of the most prone lathe components to failure.

If the one-way thrust ball bearing and other parts on the lathe spindle are damaged, the machine tool user can accurately diagnose and replace them quickly.

If the transmission shaft breaks, the machine tool user can generally solve the problem by increasing its diameter, improving its internal structure, and re arranging the gears according to the different speeds of the machine tool on site.

- Faults caused by lathe vibration

It is inevitable for the lathe to produce vibration in the machining process, but when the vibration is very intense, it will not only reduce the machining accuracy of the processed items and affect the productivity, but also aggravate the lathe wear and reduce the tool durability, which is particularly obvious for brittle tools made of cemented carbide and ceramics.

The causes of lathe vibration are: loose bolts and incorrect installation during operation; The runout of rotating parts such as tape is too large, causing lathe vibration; The radial swing of the spindle centerline is too large.

When troubleshooting the fault, pay attention to: adjust and tighten the anchor bolts; Grinding tools to maintain cutting performance; Correct the installation position of the tool tip to make it slightly higher than the working center; Correct the radial circular runout of rotating parts such as belt wheel; Try to adjust and reduce the spindle swing. If it cannot be adjusted, the angle matching method can be used to reduce the spindle swing.

- Main shaft heating leads to failure

On the lathe, the spindle is generally assembled with rolling bearings or sliding bearings, and rotates at a very high speed, resulting in large heat. The spindle bearing is the main heat source in the spindle box. If the heat produced by it is not discharged in time, it will lead to overheating of the bearing and increase the temperature of the corresponding parts of the lathe, resulting in thermal deformation. In serious cases, the height of the spindle and tailstock will be unequal. This will not only affect the accuracy and machining accuracy of the lathe itself, but also burn out the bearing and even the spindle.

The causes of spindle overheating can be summarized as follows: too small spindle bearing clearance increases friction and friction heat; In the long-term full load turning, the rigidity of the spindle is reduced, bending occurs, and the transmission is unstable and hot.

When troubleshooting the fault, pay attention to: adjust the clearance of main shaft bearing to make it suitable; Control the supply of lubricating oil and dredge the oil circuit; Try to avoid long-term load on the lathe.

- Common faults of tool holder

For the common faults of tool holder, if the cutter head does not move, the possible problems are mechanical jamming, tool holder motor burning out or contactor and control relay damage. The site shall investigate the cause of the fault step by step, narrow the scope of the fault, and finally accurately locate the fault. If a tool position on the cutter head rotates continuously, it is generally caused by the damage of the hall element corresponding to a tool position. It can be solved by replacing it. If the cutter head is not in place or over positioned during tool change, it is generally caused by the magnetic steel position being too forward or too backward relative to the hall element in the circumferential direction. When the tool holder is locked, loosen the magnetic steel plate with an internal hexagonal wrench, and then rotate an appropriate angle to make the magnetic steel relative to the hall element.

- Faults caused by loud noise

Noise is the precursor of lathe failure. Therefore, correct analysis of the causes of noise is very important to quickly find out and eliminate the faults. After the lathe is started, due to the rotation or reciprocating linear motion between the moving pairs, they contact and separate periodically, so they will produce a certain vibration due to their mutual motion.

Generally speaking, the noise will increase with the increase of temperature, load and wear, poor lubrication, etc.

Troubleshooting: adjust, repair or replace parts according to the contact condition of the moving pair to restore the due accuracy of the shaft; Check and dredge the unblocked pipeline, so that the parts to be lubricated have an appropriate amount of lubricating oil that is clean and meets the specified requirements.

- Bed saddle sinking fault

After being used for a long time, the bed saddle of the ordinary lathe often sinks, which leads to the abnormal operation of the lathe, seriously affects the working efficiency of the lathe, and even causes the complete loss of working capacity of the lathe.

The main reasons for the sinking of the bed saddle are: the wear of the guide rail surface of the bed and the wear of the guide rail surface under the bed saddle. When the daily repair and the bed saddle sinking are not serious, it is not necessary to repair the machine tool guide rail. Generally, the technical parameters of the longitudinal cutter pinion and the scale of the longitudinal moving dial on the slide box can be changed to improve the meshing condition between the longitudinal cutter pinion and the bed rack. This method has the advantages of simple and easy operation, less technical difficulty and short repair cycle, but its repair effect is limited. When the bed saddle sinks seriously or the machine tool is overhauled, the method of restoring the bed saddle height shall be adopted.

- Mechanical oil leakage fault

Oil leakage is also one of the frequent lathe faults in daily work. It will not only waste oil, cause direct economic losses, but also affect the working performance of the lathe. At the same time, long-term leakage will also bring adverse consequences to the installation of the lathe, and even affect the future work. Such problems should be dealt with as soon as possible to avoid serious consequences.

- The automatic feed handle of the chute box is easy to disengage

The reasons for the easy disengagement of the automatic feed handle of the chute box are as follows: the spring pressure of the falling worm is not enough; The inclination angle between the control board on the worm carrier and the lever changes, forcing the moving handle of the feed box to jump or the exchange gear to disengage. Troubleshooting of corresponding faults: adjust the spring pressure of the falling off worm so that the falling off worm does not fall off under normal load; Weld the control board and sharpen the hook; Adjust the spring. If the locating hole is worn, it can be riveted and re drilled.

In order to ensure the normal operation of the lathe and effectively prevent and reduce various faults of the lathe, the maintenance of the lathe has become one of the essential daily work.

- Regularly overhaul the parts and systems of the lathe that are prone to failure or have a high failure rate, such as the lubrication system, try to find the clue of the failure at an early stage and repair and maintain it in time, so as to eliminate the failure and ensure the normal operation of the lathemachine.

- In the daily maintenance, technicians should not only check the parts that may fail, but also timely test the function of each subsystem and sub module of the lathe, and systematically clean and maintain them, so as to improve the work reliability of each part, start from the daily maintenance and maximize the service life of the lathe.

- Technicians shall make records of maintenance and troubleshooting, record in detail various problems and all measures taken in the whole process from fault occurrence, analysis and judgment to troubleshooting, as well as relevant parameters and software involved.

The causes of lathe faults and their troubleshooting methods are summarized in long-term practice. Practice has proved that they have good economic and social benefits, so they are very practical and feasible. Common mechanical faults of ordinary lathe often occur in various work. Only when the staff skillfully master the working principle of lathe and have rich on-site experience can they quickly find the fault, judge the cause and eliminate it in the shortest time. Technicians should also summarize their work and try to explore and learn to repair and maintain the lathe independently, so as to combine fault diagnosis with preventive maintenance, and finally truly maximize the service life of the lathe.

If you encounter various faults when using the lathe, no matter where your lathe is purchased, we welcome you to discuss technical problems with our technicians. Please feel free to contact our technical team.