Dynamic Milling – A Modern Cost-Effective Milling Technology

In this article we will discuss what dynamic milling entails and how it is different from other manufacturing processes. It is a fascinating technology that revolutionized fabrication industries.

Let’s dive right in:

What is Dynamic Milling?

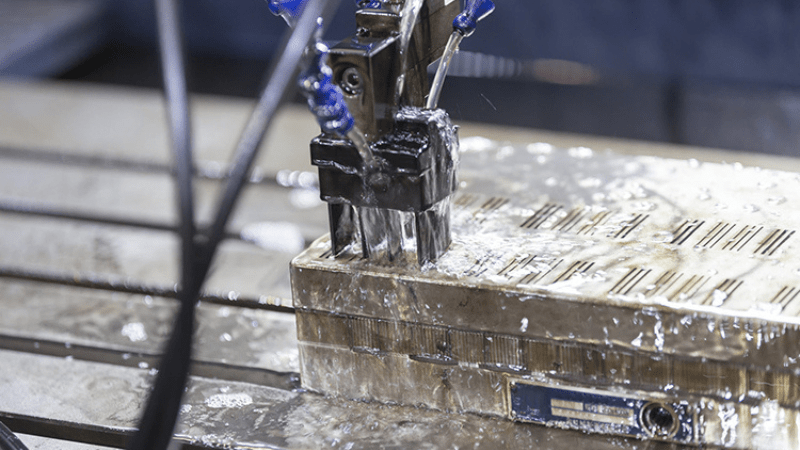

Dynamic milling is a modern computer aided manufacturing (CAM) process. It produces wanted end product through continuous, monitored removal of material from a larger raw work piece through cutting or roughing.

Advantages of Dynamic Milling

Dynamic milling technology has some rewards to its users. Some of the paybacks for adopting this machining process include:

· Longer Tool Life

Tool longevity is an important aspect in dynamic machining because the tools are expensive. Prolonging the cutting tool life is possible up to five times when the chip load is maintained during the process. A phenomenon known as radial chip thinning (RCT).

Additionally, decreased stepovers and increased stepdowns at constant chip load enables the tool to eliminate heat faster preventing tool breakdown.

· Less Process Cycle

Depending on your machine type, you can achieve a balance between amount of material removed and tool life. This you can do by slowly decreasing the stepover depth while increasing speed. As a result, you will be able to increase material removal rate while decreasing tool wear thus reducing process cycle.

· Faster Milling Process

Dynamic machining applies CAM software in its operations. This software can be used to direct the tool to produce ultra-efficient, high quality and smooth cuts within minutes.

· Smaller Cutting Tools

Since this is machine controlled, the tools are monitored when smaller cutting tools are deployed to avoid material damage at high speeds. This results in high quality material finishing.

· Reduce Secondary Finishing

Monitored smaller cutting tools can access more parts of a material during milling process. This can produce a finished material in a single operation thus eliminating the need for further finishing process in some cases.

· Operate on Lights-out

The software algorithm that operates dynamic machining is carefully developed and severally tested before it can be deployed. As a result, its operates with very high precision following designated toolpath.

This makes it safe to produce cuts unmanned and even on lights-out condition thus reducing labor costs.

· Thin-walled Components

Application areas like aerospace, medical devices and automotive manufacturers require lightweight components for their use. This can be achieved by making the components thin walled without losing their mechanical strength.

Dynamic milling technology can be used to produce precisely that by controlling the tool movement to minimize wall distortion during milling.

· Reduce Machine Wear and Tear

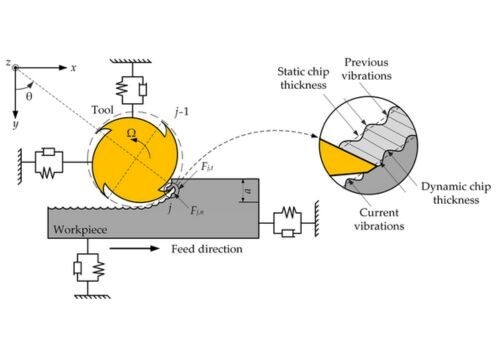

Unlike in conventional milling where vibration, lateral force and tool wear is common. Dynamic milling machine is steady thus reducing these vibrations and forces thus extending machine life.

· Conditioned for best Cut Results

Dynamic milling technology is programmed to produce precise cuts following a balance between material removal rate and reduced tool wear. This only produces precise and high quality cuts.

Recommended Dynamic Milling Machines

CNC Milling Machine

Some of the recommended dynamic milling machines are:

- A five or four-flute dynamic tool.

- A six-flute tool dynamic milling machine.

- Solid multi-flute carbide end mills.

Comparing Dynamic Milling to Conventional Milling

Dynamic milling techniques and conventional milling are both computer numerical controlled manufacturing processes but their mode of operation is quite different.

Constant operation: While dynamic milling maintains cutting tool to material contain during the process, conventional milling engages intermittently. This results in efficient, faster material removal in dynamic milling but varied material removal speed and slower production in conventional milling.

Cutting speed: In conventional milling, the cutting tool velocity is slower with lower feed to ensure tool longevity. In dynamic milling, the cutting tool speed is higher with higher feeds for good tool life through radical chip thinning.

Production cycle: Due to lower cutting speed and feeds in conventional milling, production cycle time is longer whereas in dynamic milling is faster.

Flexible Tool paths: Dynamic milling has an adaptable toolpath that is modifiable based on part geometry leading to efficient material removal rate and finishing. Conventional milling toolpath is fixed as either straight or helical and is not adjustable. This makes it fit for use for simple geometry and not complex components.

Tool durability: Higher cutting speed in dynamic milling can result in faster tool wear. This is however mitigated by the radial chip thinning as well as constant tool-material engagement. On the other hand, intermittent tool-to-material engagement results in variable cutting forces that accelerate tool wear in conventional milling.

Application: Dynamic milling is commonly applied in complex part finishes such as aerospace, automotive, etc. Conventional milling is common with production machining, repair and maintenance.

Comparing Dynamic Milling and High Feed Ramping

3d dynamic milling can be compared to high feed ramping in the following ways:

Cutting approach: Dynamic milling offers continuous cutting of the material through constant tool engagement and at high speed. High feed ramping engages the cutting tool at a shallow material depth with increased feed that gives higher material removal rate.

Cost: While dynamic milling involves complete changing of worn out tool, high feed ramping offers indexing of the worn out part only. This leads to overall saving on the tool cost. Additionally, the cost of high feed ramping tool is lower than that of dynamin milling tool.

Cutting depth: Dynamic milling is limited in terms of depth of cutting tool thus is not suitable for deep profile machining. High feed ramping cutting strategy allows it to machine deep pockets hence it is preferred for deep profiles.

Toolpath: Dynamic milling allows for complex part manufacturing due to its adjustable toolpath for efficiency and smooth finish. High feed ramping follows a rigid toolpath with a goal of high material removal.

Tool life: Both dynamic milling and high feed ramping offer tool longevity from increase material removal rate.

Applications: Dynamic milling offers milling solution for shorter milling times in aerospace, medical device, etc. High feed ramping is ideal for heavy materials roughing in aerospace and automotive industries due to its cutting approach.

Factors to Consider in Dynamic Mills Tools

Dynamic Milling Parameters

Dynamic milling tools influence how the end product will look like, tool longevity and machining operation. Selecting tools with the right quality helps achieve desired results.

· Tool Design

Tool geometry determine tool performance like vibration, surface finish material removal etc. Some of the geometries include flute design, variable pitch and variable helix.

· Quality of the Tool

High quality cutting tool offers efficient machining experience, tool durability and precise toolpath.

Tool coating: Plays a role in how the surface finish will appear, friction between material, wear resistance, durability, etc. Some of the available coatings include; Titanium Aluminum Nitride (TiAIN), Titanium Carbonite (TiCN), Titanium Nitride (TiN), etc. The choice of coating is dependent on your application.

· Material of the Tool

Dynamic milling stainless steel tools should be made from strong, tough material that is able to withstand wear and tear. Common materials for dynamic cutting tools are carbide and high strength steel. Carbide tools are preferred due to their exceptional strength and ability to resist wear and tear at high operational speed.

· Quality Standard

In order to achieve high performance standards under CAM, the tool material used must meet quality assurance standards. Sourcing tools from reputable and certified suppliers will ensure you select quality assured tools.

Applications of Dynamic Milling

Dynamic milling manufacturing process can be applied in the following industries:

- Medical devices manufacturing such as dental instruments.

- Aerospace e.g. airplane parts like swivel bracket.

- Automotive parts like fuel rails, suspension parts, etc.

- Mold and die creation

- General machining production

Conclusion

Dynamic milling is a fast efficient CAM machining operation with extended tool life due to its cutting strategy. It majors on faster material removal that ensures faster heat elimination thus preventing faster tool wear. Its commonly applied in industries that require parts with good surface finish and shirt milling time.

More Resources:

Climbing vs Conventional Milling – Source: TSINFA

CNC Machine Types – Source: TSINFA

Milling in Machining Operations – Source: WIKIPEDIA

Milling Machine Buying Guide – Source: TSINFA