What is a CNC Horizontal Lathe and How Does It Work?

CNC horizontal lathes are accurate machining tools, which are useful for the cutting, drilling, as well as shaping of workpieces with cylindrical shapes. In contrast to vertical lathes, this orients your workpiece horizontally, thereby making it rotate against the cutting tools that you control with a computer. This article discusses how CNC horizontal lathes work, its components, and the benefits it offers different industries.

What are the Main Components of the CNC Horizontal Lathes?

Chuck: Chucks hold the workpiece firmly in place when machining. This could be hydraulic, pneumatic, or manual. This depends on the requirements of your application, as well as the design of the lathe.

Bed and Carriage: Beds provide great and structural support, as the carriage also moves, ensuring that the cutting tools work with accuracy.

Headstock: This houses the motor and the main spindle, offering the required power for rotating the workpiece and at specific and controlled speeds. This helps to ensure accurate and smooth machining ensuring that it is an important component of lathes.

Control panel: This serves as an interface for the operation and programming of a CNC lathe. This allows you to monitor the progress of your machining and input commands.

Tailstock: This is optional but it is present in longer workpieces and it offers additional support, which prevents misalignment when you’re machining. This helps in enhancing stability and accuracy.

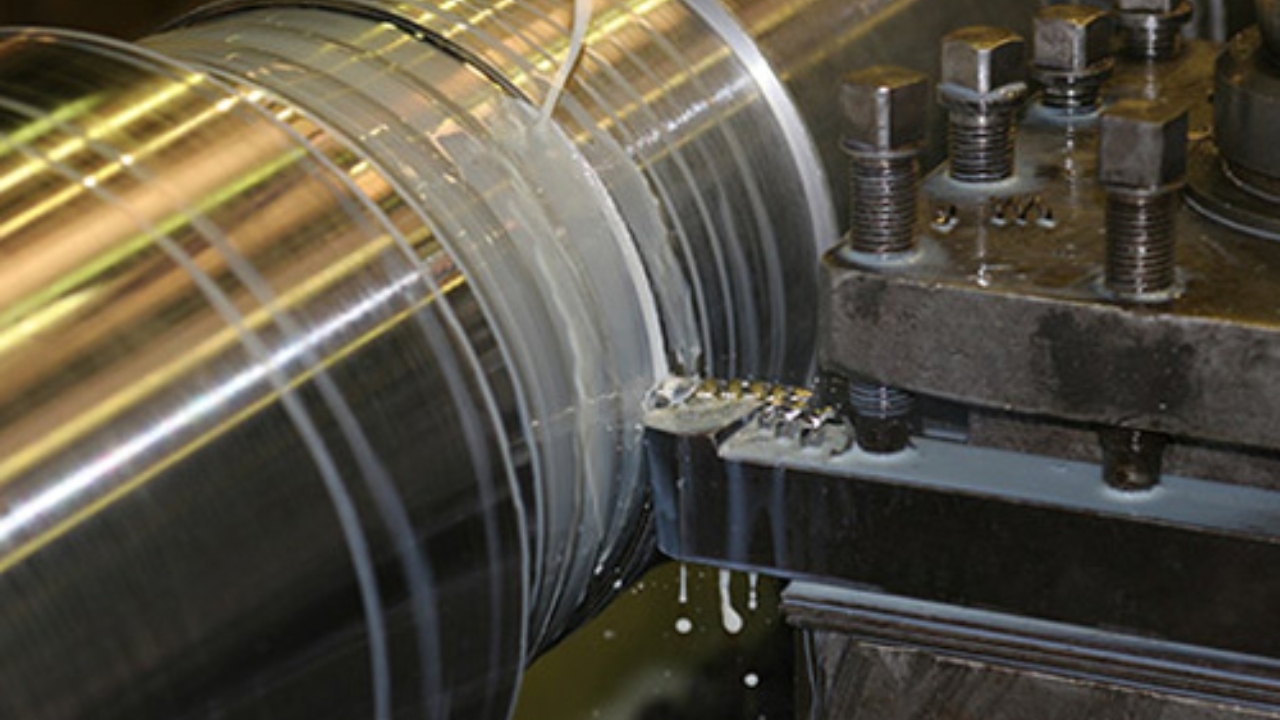

Coolant System: With this system, you can reduce friction and regulate the temperature. This prevents overheating and helps to extend the lifespan of your workpieces and tools.

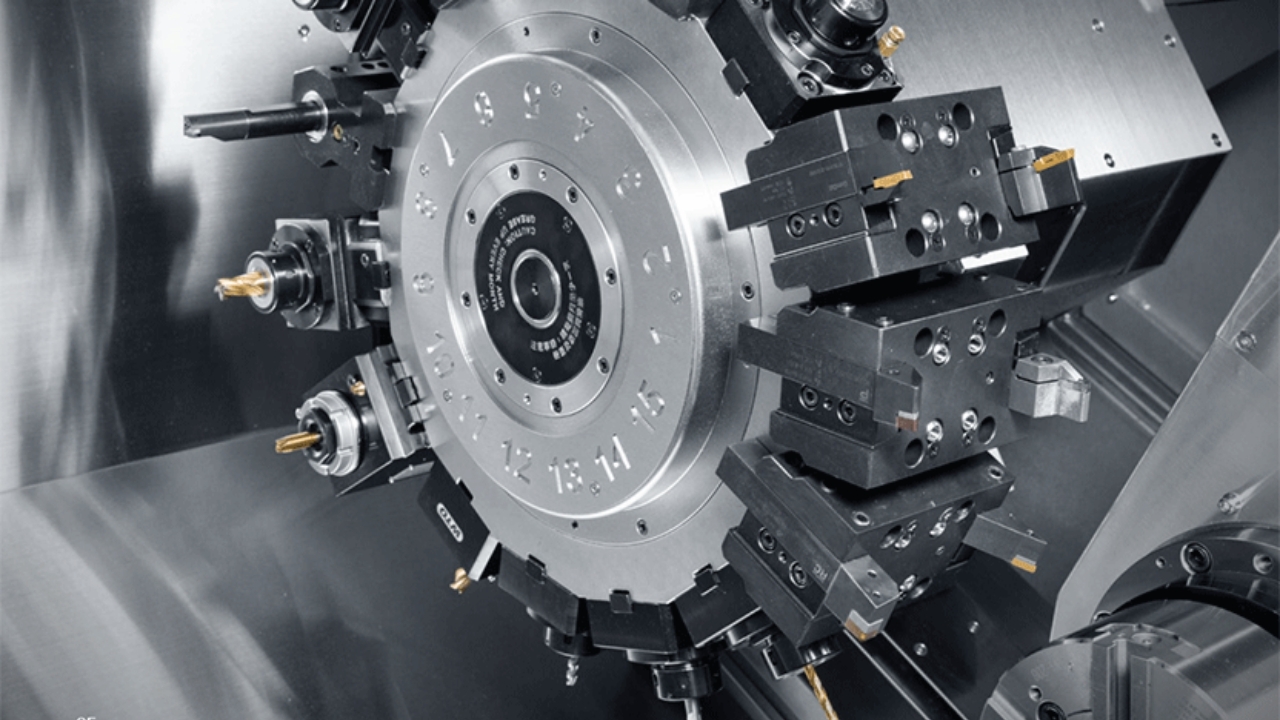

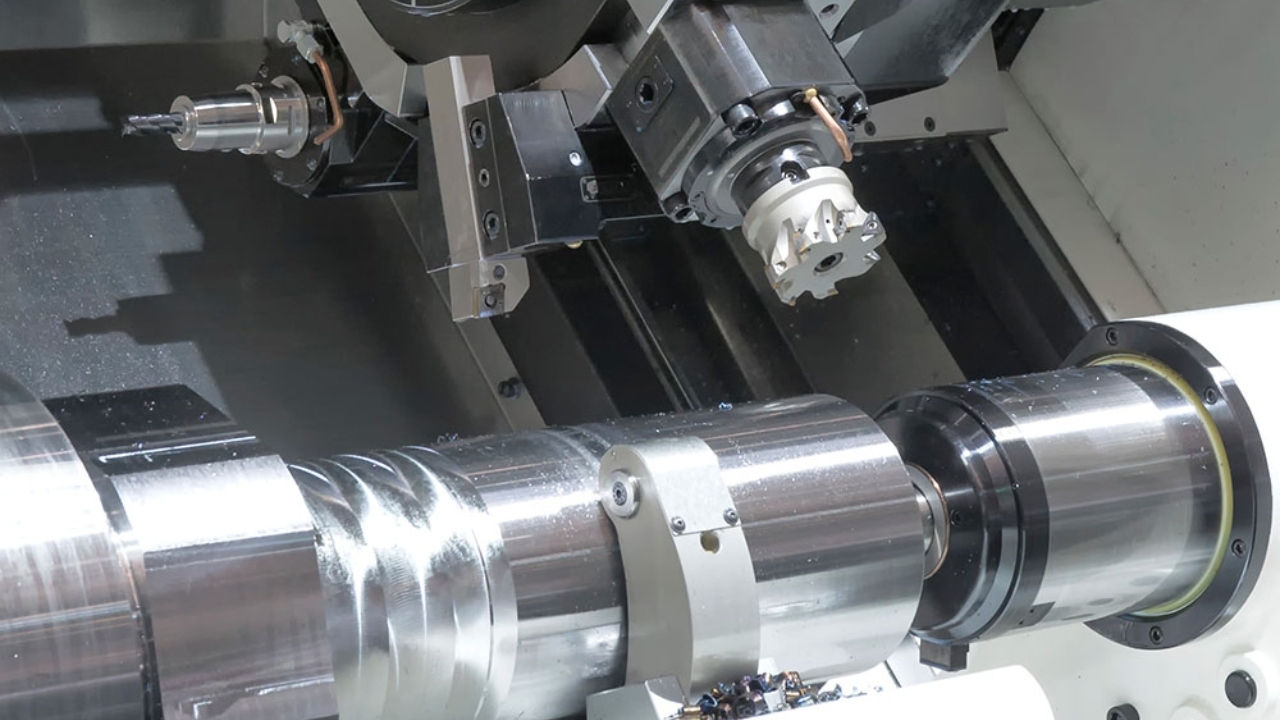

Tool Turret: The tool turret holds many cutting tools, which rotates in order to switch automatically between them. This ensures effective multi-tool operations, thereby improving the accuracy of your machining and improving your productivity.

How Does the CNC Horizontal Lathe Work?

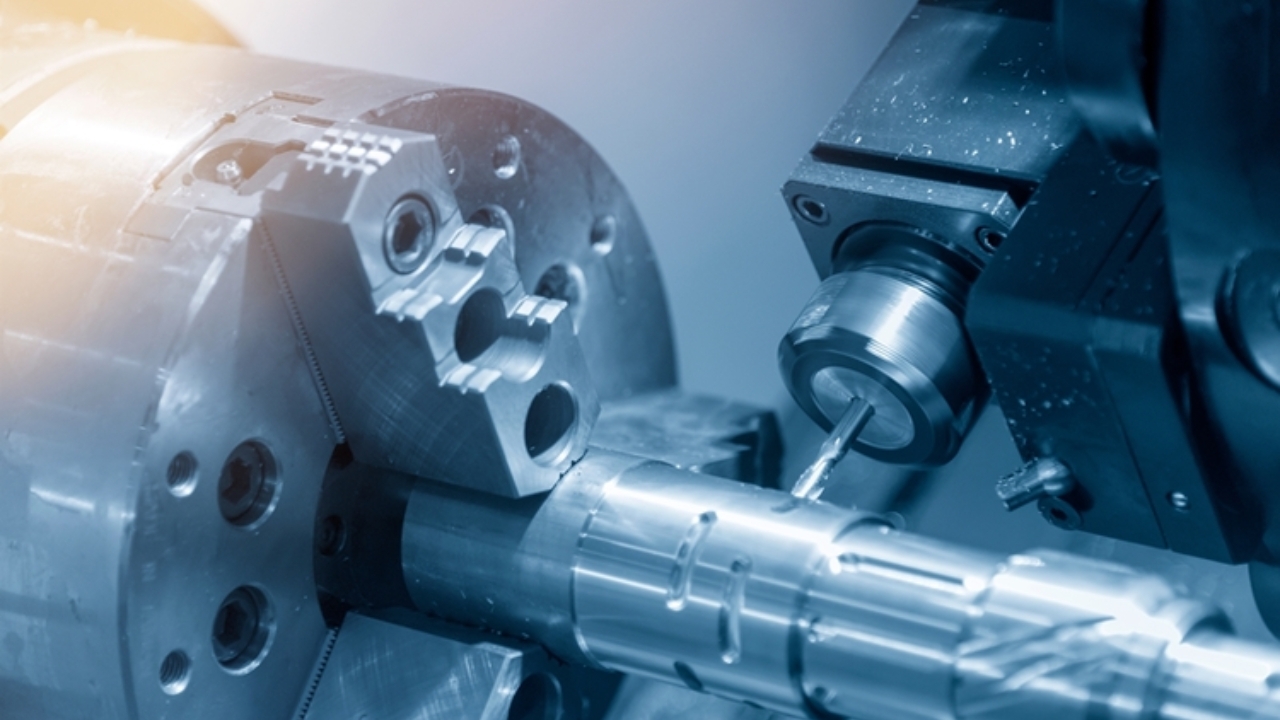

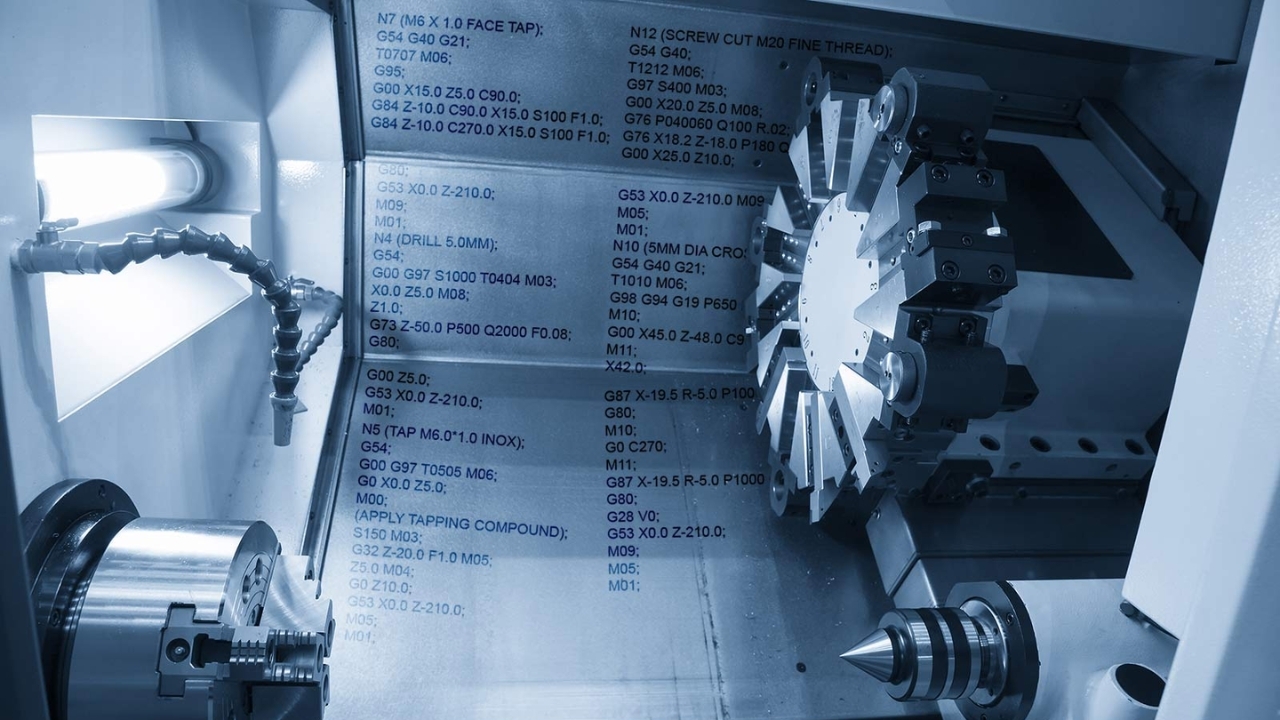

In a CNC horizontal lathe, the workpiece rotates as the cutting tools go along the X and Z axes. While the spindle secures the workpiece and spins it at regulated speeds, the cutting tools move along the X-axis and Z-axis to get your desired shape.

This machine helps you achieve precise cutting, drilling, and turning processes. Due to this level of precision, horizontal lathes are an ideal choice for automotive and aerospace industries.

Step-by-Step machining Process

During this machining process, you need to secure your workpiece by clamping it to the chuck. The CNC lathes regulate the speed of the spindle by making necessary adjustments according to the material type.

Once the spindle starts rotating, the tool turret places the cutting tool to create the required shape on the workpiece based on the instructions you program on the machine.

While these operations are going on, the coolant system regulates the temperature. Some CNC lathes feature automated tool changers which enable switching of tools during cutting operations. When you have successfully completed this process, you inspect the finished component for quality.

Difference between Horizontal Lathes Manual Lathes

CNC horizontal lathes are different from manual lathes which need manual adjustments. These lathes integrate automation and as such, they offer high precision, efficiency, and consistency. They are ideal for complex machining since they require less human intervention. CNC technology offers better efficiency which helps to increase productivity. Therefore, CNC horizontal lathes are ideal for modern manufacturing purposes.

What are the Main Types of CNC Horizontal Lathes?

CNC horizontal lathes are available in different types. Each type operates differently and as such, has its unique advantages and limitations

2-Axis CNC Lathe

In a 2-axis lathe, your cutting tool passes along the X and Z axes as the spindle rotates the workpiece. You can use CNC lathes for machining operations like turning, drilling, and facing. Due to their high accuracy and efficiency, these lathes are ideal for creating cylindrical components. However, one of the limitations of these lathes is that they can’t handle complex geometries. 2-axis lathes are commonly used in manufacturing automotive components like fasteners and shafts.

3-Axis CNC Lathe

This type of CNC lathe has a third axis, which is the Y-axis. The additional axis offers better machining capabilities like milling and off-center drilling. Due to this, you can use this CNC lathe to produce more complex parts without the need to reposition your workpiece. A 3-axis CNC lathe is commonly used in industries where complex geometries are crucial.

Multi-Axis CNC Lathe

These types of CNC lathes have more than 3-axis. This means you can use them to machine multiple angles simultaneously. These CNC lathes have other features like live tooling and enhanced automation. Therefore, you can use them to machine complex parts and other components that require high precision. Due to their multiple axes, you don’t need to spend much time on setups and machining.

Swiss-Type CNC Lathe

You use this type of CNC lathe for machining small-diameter components. Swiss -type CNC lathes have a guide bushing that enables you to perform machining operations with high precision. You can use these lathes in applications that require micro-machining e.g. electronics and medical industries.

What are the Benefits of CNC Horizontal Lathes?

CNC horizontal lathes are unique in the way they operate. Therefore, they have their distinct benefits which include:

High-precision machining

These lathes integrate high-speed rotation and accurate cutting. With CNC horizontal lathes, you can achieve repeatable machining. Also, these lathes require minimal human intervention since they integrate computer-controlled systems. You can achieve consistent and efficient results when you use these lathes in complex machining operations.

Suitable for different material types

These lathes can work with different types of materials like composites, metals, and even plastics. You can adjust the spindle speeds based on the hardness of your material. Also, you can use it to machine both hard and soft materials with precision.

Offers enhanced support

Horizontal CNC lathes offer better support when you use them on long workpieces. These lathes have a tailstock which prevents your workpiece from bending and vibrating. They offer stability and support, hence, you can use them for machining elongated parts like shafts.

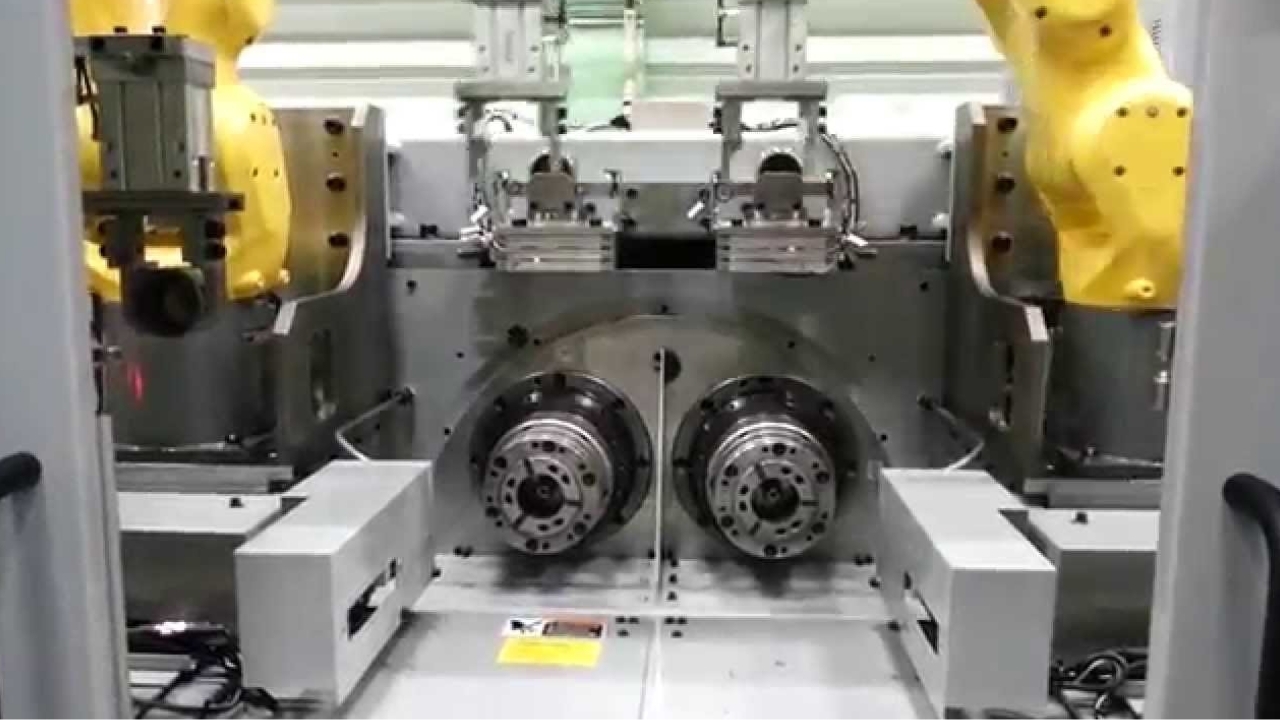

Automated tool changers

CNC horizontal lathes come with automatic tool changers which enable you to switch cutting tools between operations. Therefore, you can switch from one machining operation to another. For instance, you can switch between milling, cutting, and drilling. This helps to improve efficiency and productivity.

Which Industries Use CNC Horizontal Lathes?

CNC horizontal lathes are common machines used across industries that require high-precision manufacturing. These industries include:

Automotive Industry

Automotive manufacturers integrate CNC horizontal lathes in the production of automobile parts like wheel hubs, engine components, brake discs, and more. Due to the level of precision these lathes offer, you can use them to design high-performance components.

Aerospace Industry

These lathes are capable of creating high-precision parts like aircraft fittings, turbine shafts, etc. Most materials used in aircraft production have high -strength. CNC lathes excel in machining such materials with high precision, therefore, they are a considerable choice amongst aircraft manufacturers.

Medical Sector

CNC lathes are a great choice for manufacturing medical components like surgical instruments and dental components. Due to their precision and efficiency, they can create high-quality medical components safe for patients.

Manufacturing Industry

The Manufacturing industry is a vast one that requires the use of high-precision machining. CNC lathes offer efficiency and accuracy, hence you can use them in producing complex parts and components.

Maintenance and Safety Considerations for CNC Horizontal Lathes

Apply Lubricant Regularly

You can maintain your CNC lathes by applying lubricant regularly. This will help to reduce friction in certain parts of the machine. Also, you can carry out routine inspections to detect any signs of misalignment or wear.

Check Coolant System

The coolant system in your CNC lathe prevents your machine from overheating. Overheating can cause machine failure, therefore, it is important you always check your coolant system to ensure smooth functioning of your CNC lathe.

Replace Worn Out Tools

Cutting tools get worn out as time goes on. This is normal, however, failure to replace worn out tools can cause further issues. Once you detect any worn out tools, ensure you replace them as soon as possible.

Follow Safety Guidelines

Machine operators need to follow safety guidelines before and during machining. You need to wear your protective gear before the machining operation begins. Read machine guidelines before you start operating. Prevent any form of contact with parts that are in motion and keep your space organized always.

What are the Future Trends of CNC Horizontal Lathes?

Integration of Artificial Intelligence

The integration of AI in CNC horizontal lathes will help transform its capabilities. With AI, these machines will offer real-time monitoring and be able to ensure process optimization. Also, automation will reduce human intervention and increase productivity.

Advanced cutting tool materials

Some materials can help to increase the longevity of cutting tools. Materials such as polycrystalline and ceramic are perfect options for extending tool life. Also, the use of advanced coatings can ensure higher cutting speeds and improve the ability of tools to resist heat.

Great manufacturing capabilities

Manufacturers are beginning to produce CNC machines that feature both additive manufacturing and subtractive machining. These are hybrid machines that offer better efficiency and allow rapid prototyping. These machines will serve as a game changer in the high-precision manufacturing industry.

Conclusion

CNC horizontal lathes can handle different machining operations like drilling and turning. These lathes are versatile as you can use them on different materials ranging from titanium, to steel and polycarbonate. Therefore, they are widely used across different industries like medical, automotive, and aerospace. Constant innovation in automated technology and artificial intelligence will contribute to the evolution of CNC lathes. You can visit Tsinfa if you wish to invest in high-quality CNC horizontal lathes.