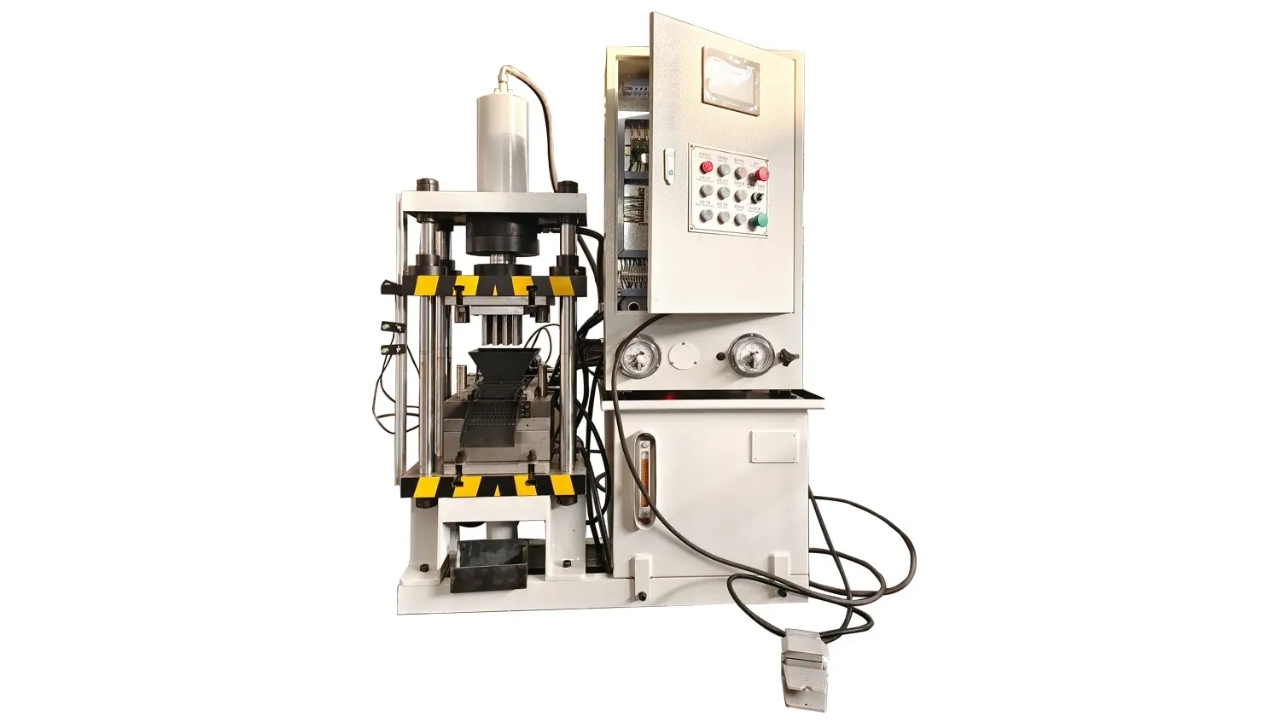

Powder Forming Hydraulic Press

The TSINFA powder-forming hydraulic press or powder compacting press compresses composite metallic powders of alloys, silicon, and carbon into definite shapes, sizes, and densities. Our varieties may use pressures as high as 50,000 psi to mold and form materials within a few seconds.

Need a quote? Give us a call at +86-15318444939, and talk to one of our expert reps.You can also fill out our : contact form

Powder Forming Hydraulic Press: Types, Applications, and Benefits

What is a Powder Forming Hydraulic Press?

A powder forming hydraulic press is a machine that uses hydraulic pressure to form complex shapes from powder compounds. Hydraulic presses work by applying pressure to a confined fluid, which causes the pressure to change throughout the entire fluid. A piston inside the press acts as a pump, applying a small mechanical force to a small area of the sample. It is used in various industries like automotive to aerospace.

Types of Powder Forming Hydraulic Presses

-

Axial Powder Presses

Axial powder forming hydraulic presses shape metal powder into solid components with a defined geometry. This process efficiently produces large quantities of complex components, and the parts are often close to their final shape. It can create various shapes and maintain a high-quality level. It also tends to be cost effective and in most cases, the pressed parts do not require further pressing.

-

Isostatic Presses

Isotactic powder forming hydraulic presses are used to form the powder having the required shape using isostatic pressure, which is the pressure exerted on the product from all directions. This step can be carried out at room temperature and pressure, or under temperature and pressure conditions higher than those of room temperature and pressure.

-

Four-Column Hydraulic Presses

Four-column presses have a stable layout and the ability to work in operations creating components with high levels of accuracy. They are especially useful when there are four support columns since force can be distributed evenly when compacting. They are applied in operations that require small to medium production of parts in the automotive, electronics, and medical fields.

-

Single-Column (C-Frame) Hydraulic Presses

C-frame presses are lightweight and highly compact machines to increase rigidity and reduce complexity. These presses are perfect for applications that need moderate pressure and ideal for small up to medium size parts. They are particularly used in research, development, and low-volume production and are common in different sectors.

-

Multi-Action Hydraulic Presses

Multi-action presses work in ways that the pressure is applied from different directions such as the axial and radial. This is useful for making parts with hard to mold shapes and density variation and is widely used in aerospace industries and industries or electronics.

-

Servo-Hydraulic Presses

Servo-hydraulic presses are developed with force and speed control by using servo motors. This capacity enables highly accurate compaction appropriate in application areas with tight tolerances and intricate shapes such as medical device production.

-

High-Speed Powder Compacting Presses

These presses are suitable for large and frequent production as they are characterized by low production time. They are particularly of great use in businesses whose operations depend on the velocity of certain parts instead of their quality, for instance, the automobile or the electrical goods industry.

Benefits of Using Powder Forming Hydraulic Presses

-

Enhanced Material Properties

Powder forming presses allow the formation of parts with better material characteristics, density, and strength. It is particularly important for parts that are likely to experience some form of adverse condition such as aerospace and automobile parts.

-

Precision and Complexity in Component Design

Hydraulic presses can develop very close tolerances and shapes that cannot otherwise be attained using other modes of manufacturing. It also makes it possible to replicate very complicated shapes, which are very accurate and which are required in such fields as, health facilities and electronics.

-

Cost-Effectiveness and Material Efficiency

Powder metallurgy also helps to minimize overall material wastage since powders of metal are used during the process of production, which can be reused. This results in lower consumption of raw material leading to this being cheaper than the normal industries where it is important to achieve high levels of precision.

-

Versatility in Material Processing

Powder forming presses can be applied when utilizing numerous kinds of materials such as metals, ceramics, and composites. Such versatility enables various manufacturers to evaluate different materials that may suit the industry requirements.

-

Scalability and Adaptability

Many of these presses can be chosen depending on the amount of presses an individual wants ranging from small-scale production to a massive production scale. In other words, powder forming presses can be applied to any organization, be it research and development or a high-volume production company.

-

Energy Efficiency

The overall energy efficiency of a powder forming press is usually higher than that of forging or casting techniques. Their consistency in exerting pressure and speed ensures that little energy is consumed, which is both environmentally and economically beneficial.

Applications of Powder Forming Hydraulic Presses

-

Automotive Industry

The automotive industry is one of the most frequent users of powder forming presses to manufacture gears, bearings, and structural parts. The fact that aluminum castings offer high strength-to-weight ratios makes them suitable where weight control is desirable such as with vehicle structures that seek lightweight.

-

Aerospace Industry

Aerospace requires parts that are made accurately and of very strong material. These needs are met by powder forming presses, which can manufacture complex components such as turbine blades and many other airframe structures from such alloys.

-

Medical Devices

They utilize powder forming presses because of the intricate and high part detail achievable when developing implant, prosthetic, and surgical instrument parts. This means there is an effective way of improving performance and making the material more biocompatible.

-

Electronics Industry

In the electronics industry powders are used in the production of connectors, housings, and other components including heat sinks. The nature of the powder forming presses is that they can produce small forms with high precision and reproduce them to a very small tolerance.

-

Tool and Die Making

Powder forming presses in tool-making work by generating proper die and mold required in the manufacturing of parts. These presses do this to meet the tight tolerance necessary in the manufacturing tools that are used in the next steps of making other products.

-

Consumer Goods

Residential appliances or personal electronics are some examples in which powder forming presses deliver high and robust parts in various consumer products. The features involving precision and cost effectiveness therefore make them appropriate for use in the manufacturing of parts that require high standards of performance and durability.

TSINFA Powder Forming Hydraulic Press

We manufacture two post hydraulic presses and several other premium quality sophisticated machines. In addition to employing quality materials for production, we also receive quality customer service at an affordable price quality. Promoting the customers’ success and value is also a key at TSINFA. We remain fully committed to how best to serve the interests of customers more so in the innovation of the product’s design and processing technology.

FAQs

What factors influence the selection of a hydraulic press for powder forming?

Some of them include the type of material, the force needed to compact the part, the geometry of the part, the time to form cycle, and the quantity of parts needed.

Are there size limitations for parts produced by powder forming hydraulic presses?

Yes, size limitation is true depending on the limitation of the press. This is the key reason why large presses can accommodate large components while small presses have higher accuracy in small parts.