Everything You Should Know About Vertical Turning Lathes (VTLs)

A vertical turning lathe is a machine that cuts, shapes, and drills heavy workpieces. This machine features a vertical structural design which offers extra support during machining. This vertical structure helps the machine to hold workpieces firmly during the machining process. In this article, we will discuss everything you need to know about vertical turning lathes.

Main Components of a Vertical Turning Lathe

A CNC vertical turning lathe comprises different components, with each playing a significant role in its functioning.

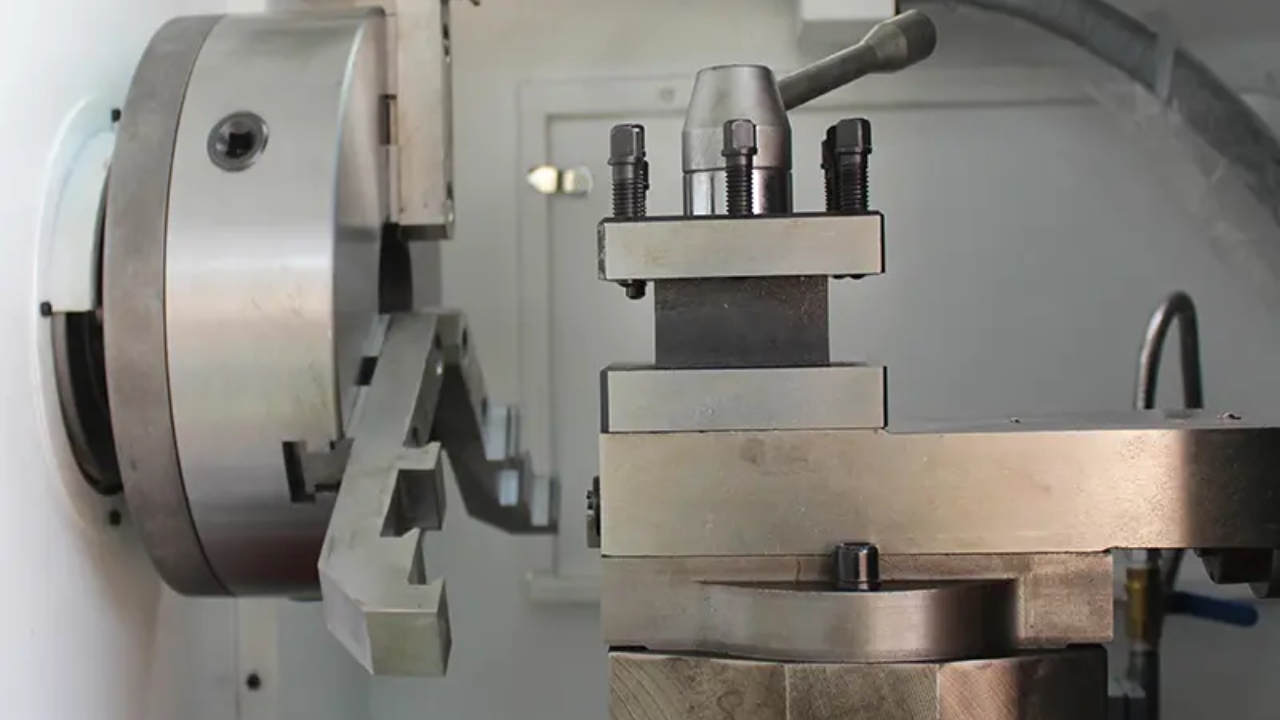

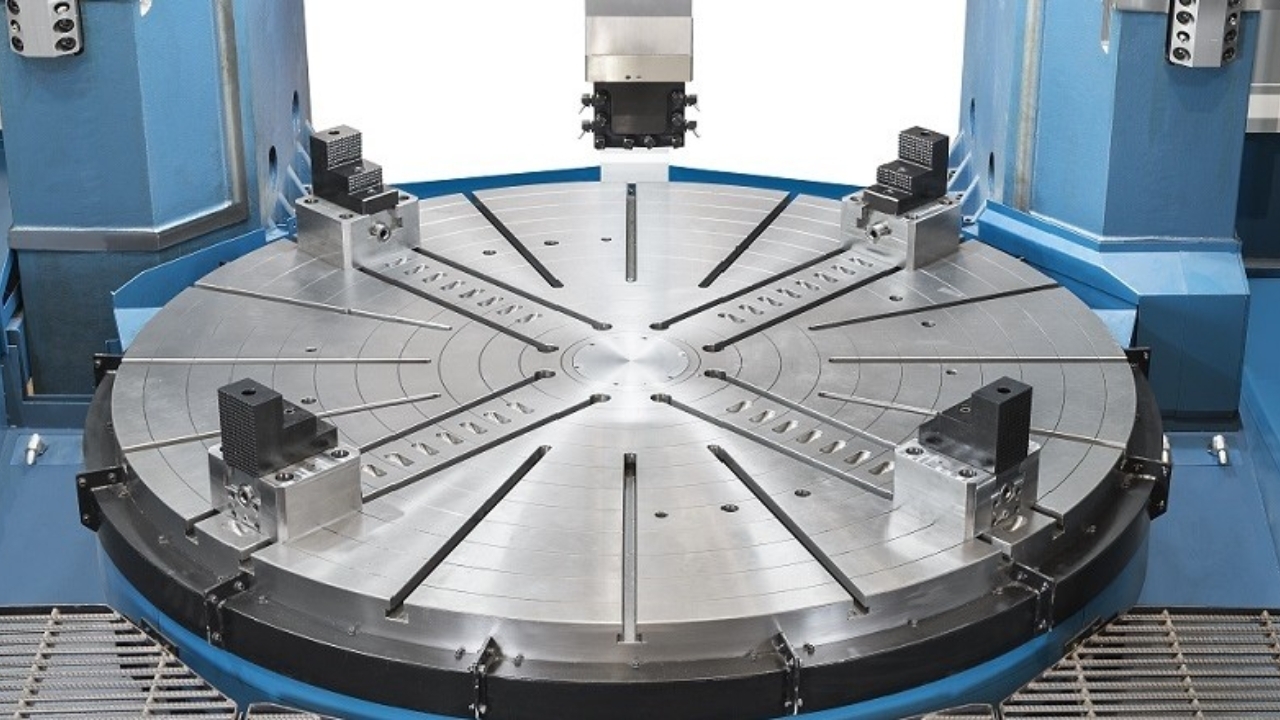

Chuck

Also known as the rotary table, this part secures the workpiece and rotates it while you are machining. It helps you hold your workpiece on place and ensures good balance, particularly when working with large-diameter components.

Machine bed and column

These components ensure stability and rigidity during heavy-duty operations. They reduce vibration and helps to extend tool life

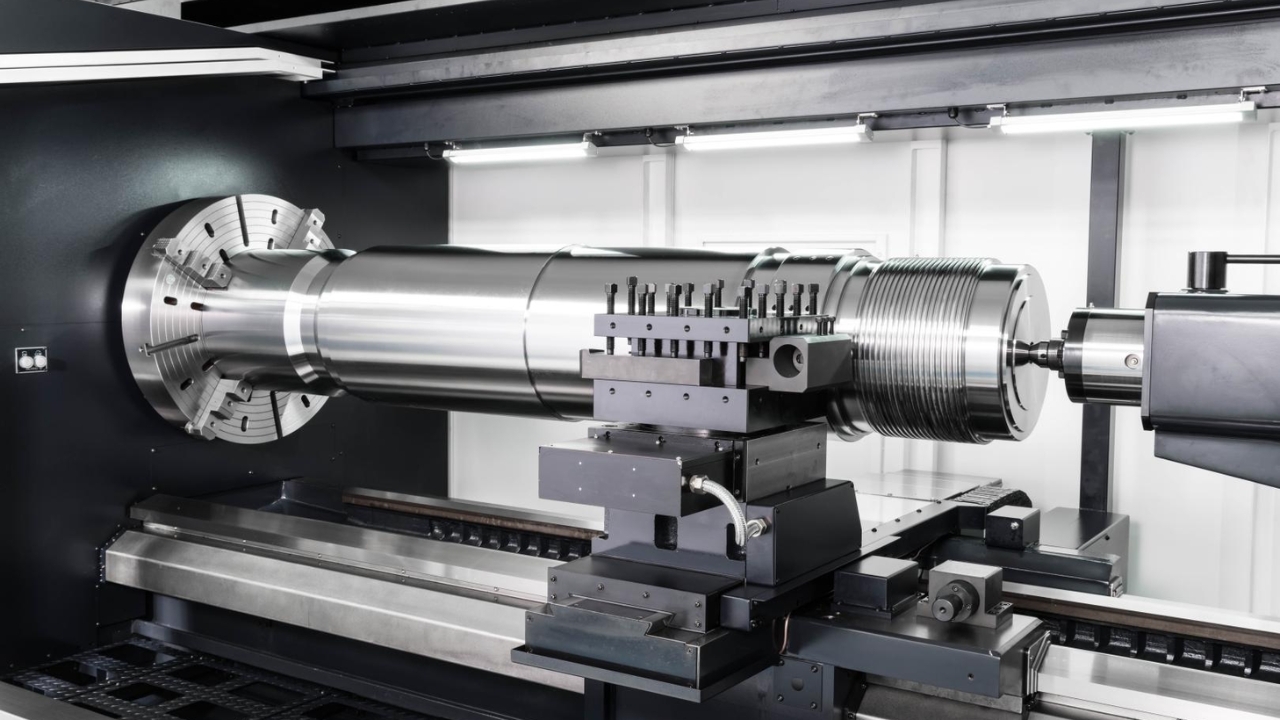

Tool turret

This component helps you switch between cutting tools during the machining process. A tool turret uses automation to switch tools and as such, allows you to switch between different operations.

Coolant system

The coolant system in a CNC lathe helps to regulate the temperature during machining. It helps you achieve optimal machining performance by preventing overheating.

Main Spindle

This significant part of a CNC vertical lathe is the powerhouse of the chuck. The main spindle rotates the workpiece in a controlled manner. It determines your cutting speed and as such, impacts your machining accuracy.

CNC Control system

This part helps you to achieve repeatable consistency and precision. A CNC system programs your machine automatically, while maintaining accuracy.

How Does a Vertical Turning Lathe Work?

As the name implies, a vertical turning lathe works by placing your workpiece in a vertical position on a chuck. The chuck spins your workpiece as the cutting tool gives it your desired shape. The vertical structure ensures enhanced support, especially when working with large workpieces. Also, this minimizes the pressure on the spindle and enhances stability.

When working with a vertical lathe, you secure your workpiece on the chuck with a clamp. The chuck, also known as the rotary table, rotates and the cutting tool moves along horizontal and vertical axes to carry out different operations like drilling, cutting, and turning. During this process, the CNC control system uses automation to help you achieve accuracy.

Unlike horizontal lathes, vertical lathes provide better stability and accuracy. Due to these added benefits, they are suitable for large-scale industrial machining.

What are the Main Types of Vertical Turning Lathes?

Single-Column

This type of vertical turning lathe has one vertical column that supports your cutting tool. You can use this lathe when working on medium-sized workpieces. Although these lathes offer efficient results, they aren’t suitable for heavy-duty machining.

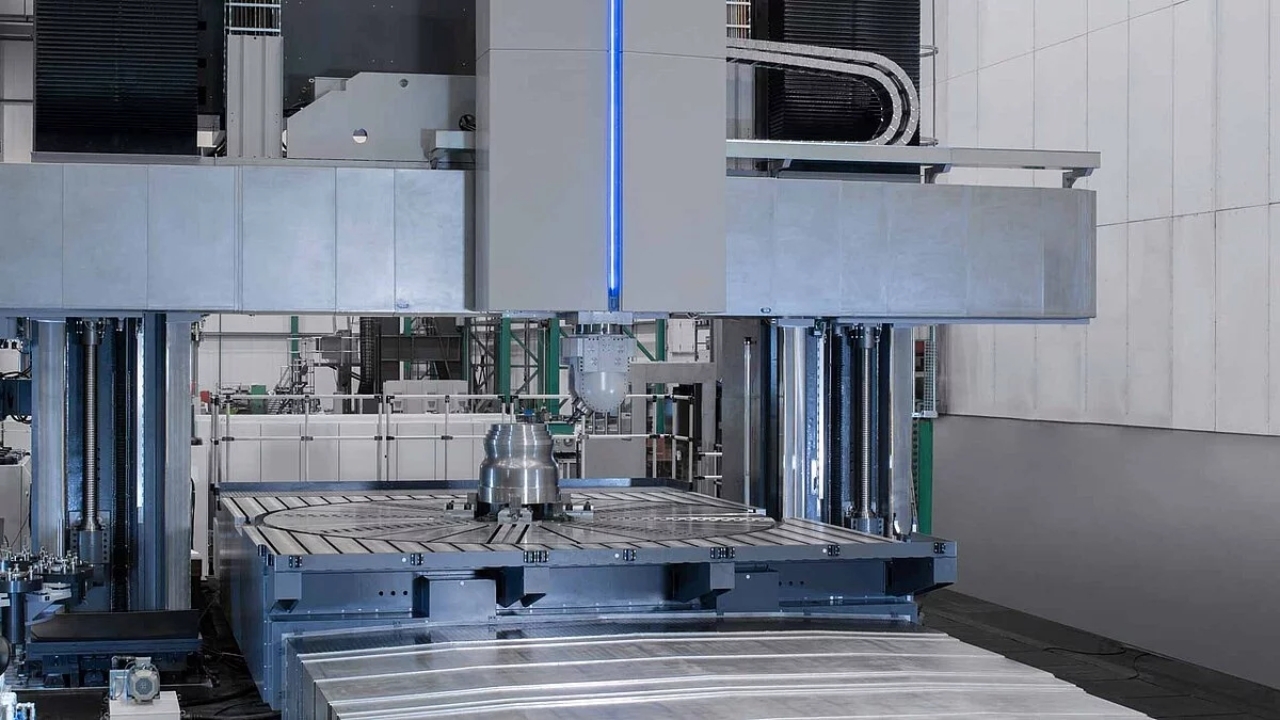

Double-column

A double column vertical turning lathe can handle heavy-duty machining it features two vertical columns which offers better stability. This enhanced stability reduces vibrations and offers precision during the machining process.

CNC vertical lathe

A CNC vertical turning lathe integrates automation in the machining process. This helps you achieve high-accuracy and consistency. This type of lathe helps you make complex cuts and allow automatic tool changes during operation. Due to the integration of automation, this late provide highly-accurate and efficient results. Therefore, they are suitable for large-scale manufacturing.

Manual vertical turning lathe

This lathe requires human intervention during machining. You have to control the whole process manually. It is ideal for low-volume production and specialized operations where you need to make manual adjustments.

Benefits of a Vertical Turning Lathe

High precision

Vertical Turning lathes have a rigid structure which reduces vibration during machining. This rigidity helps you achieve high-precision operations like drilling and cutting. You can even use them in tough materials like titanium.

Enhanced support

Vertical Turning lathes offer better support and stability, therefore, you can use them on heavy and large workpieces. These lathes feature gravity-assisted vertical design that secures the workpiece firmly. Due to this design structure, these lathes are highly-preferred amongst heavy machinery manufacturing.

Less floor space

Vertical Turning lathes are a great option in applications where space is a major concern. These lathes place your workpiece in a vertical position, making it require less floor space during machining.

Reduced tool deflection

Tool deflection is a common issue during machining operations. However, the vertical orientation of these lathes and the rigidity they offer prevents vibration. Vibration is one of the major causes of tool deflection. Therefore, reduced vibration will minimize tool deflection. This helps you achieve better accuracy and fine surface finishes.

Maintenance Tips for Using Vertical Turning Lathes

Take safety measures

Make sure safety protocols to avoid accidents and ensure smooth machine operation. Wear your protective gear, avoid contact with moving parts, and secure your workpiece firmly.

Regular inspection

One of the best ways to maintain your lathes is by ensuring frequent inspection. Check your rotary table , cutting tools, and other parts of your lathes regularly. This will help you detect any signs of wear or misalignment. Check out your tooling system for any worn-out or loosely-fit tools and fix the problem immediately.

Maintain coolant system

The coolant system is a crucial part of a vertical lathe. It prevents your machine from overheating by ensuring an optimal temperature during machining. Therefore, it is important you check the flow rates and coolant levels of this system. If you notice your coolant is contaminated, replace it immediately to prevent corrosion.

Future Trends of Vertical Turning Lathes

Automation and Robotic systems

Today’s vertical turning lathes now integrate automation and robotic systems to ensure accuracy and efficiency. This helps to minimize manual labor and speed up the production process. Therefore, these lathes can handle large-scale manufacturing.

Predictive maintenance

Vertical Turning lathe manufacturers have started integrating smart sensors on these machines. This will encourage predictive maintenance as smart sensors monitor machines in real-time and easily detect potential issues. With predictive maintenance, there will be reduced downtime and repair costs.

Advanced tool coatings

Development and innovation in tool coatings can improve tool life. Modern cutting tools now feature diamond and ceramic. This helps you achieve finer surface finish and improve productivity.

Applications of Vertical Turning Lathes

There are many areas where vertical turning lathes have proved to be efficient and suitable for manufacturing. Common industries like automotive, aerospace, and medical industries.

Automotive

Automotive industries integrate vertical turning lathes in the production of complex components like gear shafts and brake discs. These lathes provide precision and consistency and as such, are ideal for manufacturing critical automotive components.

Energy sector

Vertical Turning lathes are important machines used in the energy sector to manufacture components used in oil and gas industry. Some of these components require precise machining process due to their complexity. Therefore, these lathes offer the required precision to manufacture these components.

Aerospace

Vertical turning lathes are commonly used in the aerospace industry due to their precision and efficiency in handling heavy-duty materials. Also, these lathes are suitable for large-scale production of complex parts like landing gear and turbine housing.

Heavy Machinery

In heavy machinery manufacturing, vertical turning lathes help to produce critical parts such as equipment casings, cylinders, and shafts. Since these lathes are capable of handling heavy-duty machining tasks, they are a popular choice amongst manufacturers.

Conclusion

Vertical Turning lathes are efficient machines used for producing high-quality and heavy components. Due to their versatility, these machines are commonly used in various industries like aerospace, energy, manufacturing, and more. Also, they are efficient, stable, and precise. Therefore, they are a great choice in high-precision and large-scale manufacturing.

The advancement in technology and integration of automation has contributed to the development of CNC lathes. Therefore, modern CNC lathes ensure optimal performance and increase productivity. You can visit Tsinfa. for your cutting-edge vertical turning lathes.